Table of Contents

In modern mineral processing and cement production, grinding systems play a critical role in reducing particle size for downstream operations. However, these systems are energy-intensive, often accounting for a significant portion of operational costs. One effective method to improve efficiency and reduce energy consumption is the use of high-quality casting balls in ball mills.

1. The Role of Casting Balls

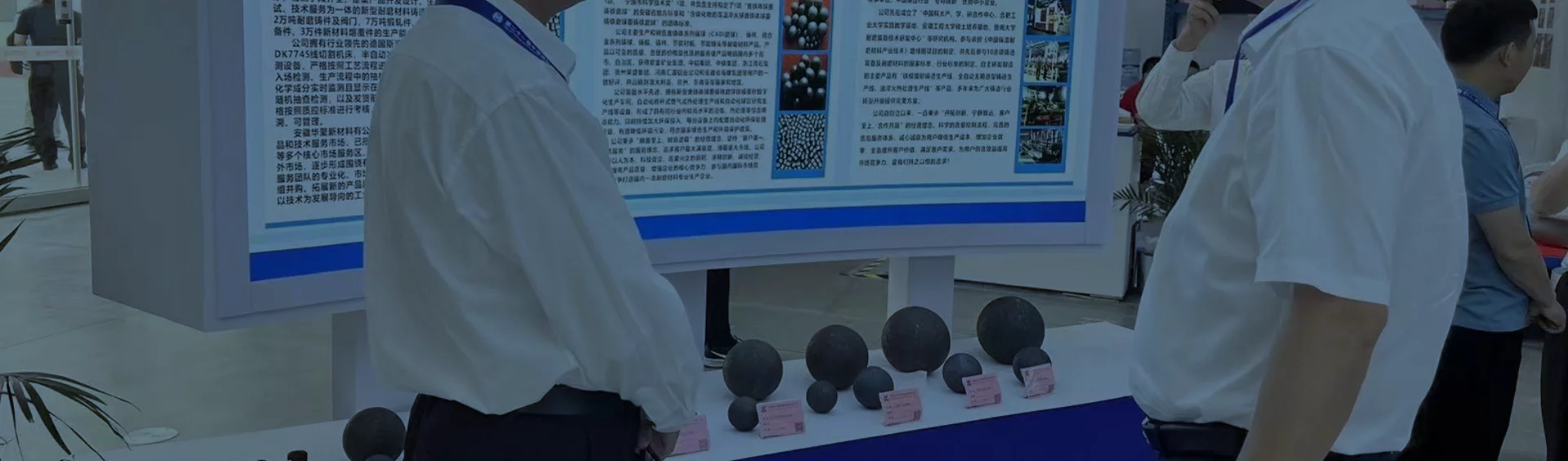

Casting balls, typically made from high-chrome or alloy steel, serve as the grinding media inside ball mills. Their primary function is to impact and grind the raw material into finer particles. The material properties and design of the balls have a direct influence on the grinding efficiency and energy consumption of the mill. High-density and wear-resistant casting balls maintain their shape and size over prolonged operation, ensuring consistent grinding performance.

2. Optimizing Grinding Efficiency

One key factor in energy reduction is optimized impact and grinding efficiency. Uniformly sized and high-quality casting balls create a consistent charge in the mill, which promotes uniform energy transfer from the rotating mill to the material. This reduces over-grinding and minimizes energy wastage. Moreover, the hardness and density of the balls allow for higher impact force with less friction, meaning fewer rotations are required to achieve the desired particle size.

3. Durability and Reduced Maintenance

Lower-quality balls wear faster, requiring frequent replacement and leading to mill stoppages. These interruptions not only increase operational costs but also reduce energy efficiency, as restarting the mill consumes additional energy. By using durable casting balls with high wear resistance, plants can operate longer without interruption, stabilizing energy consumption and improving overall productivity.

4. Customized Casting Balls for Specific Applications

Casting balls can be customized for specific grinding systems. For example, different sizes or alloy compositions may be used for dry or wet grinding, hard or soft ores, and specific mill designs. Tailoring the casting balls to the application ensures optimal energy usage and maximizes throughput while minimizing waste.

Selecting high-quality casting balls is a simple yet effective strategy to reduce energy consumption in grinding systems. By improving grinding efficiency, minimizing wear, and stabilizing mill operation, casting balls help plants lower operational costs while maintaining consistent product quality. For industries such as cement, mining, and mineral processing, investing in durable and well-designed casting balls offers tangible energy and cost-saving benefits.