Table of Contents

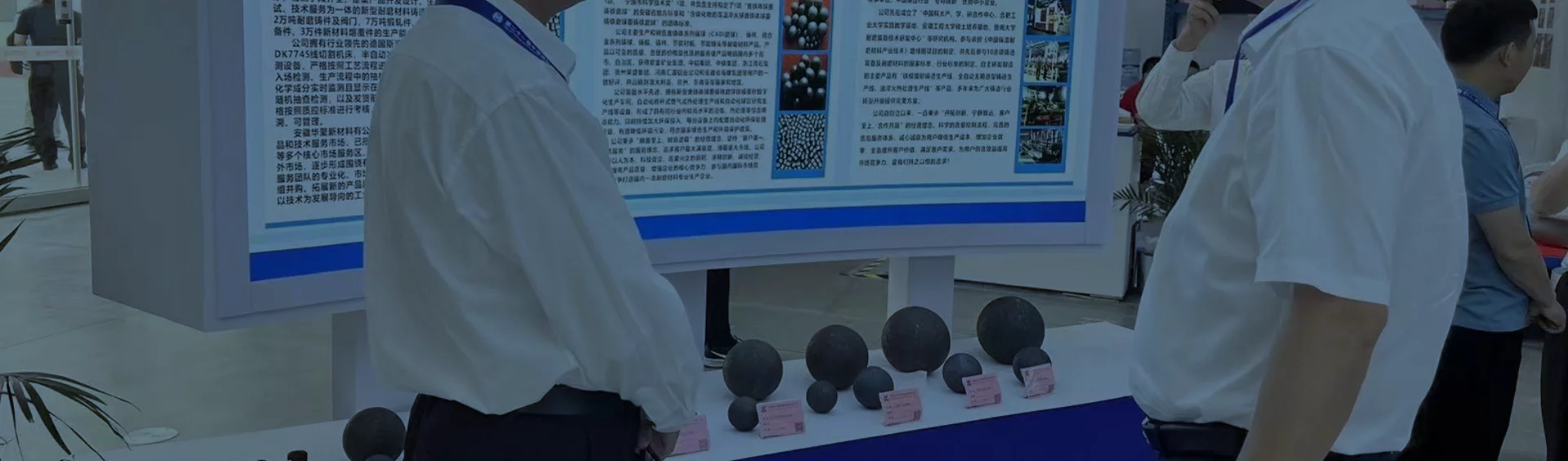

In the mining, cement, and power industries, grinding balls are essential consumables used in ball mills to crush and grind raw materials. While they may look similar, not all grinding balls are made the same way. The two most common types are cast grinding balls and forged grinding balls. Understanding their differences is important when choosing the right material for your specific project.

1. What Are Cast Grinding Balls?

Cast grinding balls are manufactured by pouring molten metal into molds. The most common material is high chrome alloy, which makes them very hard and wear-resistant. Thanks to their high hardness, cast balls are often used in cement plants and thermal power plants, where fine grinding and resistance to abrasion are more important than impact strength.

- Advantages of cast grinding balls:

High hardness and excellent wear resistance

Good for dry grinding environments

Suitable for cement, chemical, and thermal power industries

- Limitations:

Brittle compared to forged balls, which means they may break under high impact

Less effective in large-scale mining operations where the ore is harder and requires heavy grinding

2. What Are Forged Grinding Balls?

Forged grinding balls are made by heating steel rods and then using forging machines or hammering to form balls. This process makes the internal structure more compact and improves toughness. Forged balls are usually made of carbon steel or alloy steel and are widely used in mining industries, especially for grinding hard ores like gold, copper, and iron.

- Advantages of forged grinding balls:

High toughness and impact resistance

Low breakage rate, even in heavy-duty grinding conditions

More suitable for mineral ore processing in mining

- Limitations:

Wear resistance is slightly lower compared to high chrome cast balls

Can be more expensive in some cases

3. How to Choose Between Cast and Forged Grinding Balls

The choice depends mainly on your working conditions and application:

For mining and ore processing: Forged grinding balls are usually the better choice because they can withstand heavy impact and are less likely to break. They also offer better grinding efficiency for hard minerals.

For cement plants or thermal power plants: Cast grinding balls, especially high-chrome types, are more suitable because they perform well in dry grinding and are very resistant to wear.

For cost control: Forged balls may last longer in mining applications, reducing replacement frequency. Cast balls, while sometimes cheaper, may need to be replaced more often in high-impact environments.

4. Conclusion

Both cast and forged grinding balls have their own strengths. Cast grinding balls offer excellent wear resistance, making them ideal for cement and power plants. Forged grinding balls provide high toughness and durability, making them the top choice for mining operations. By carefully evaluating your industry, ore type, and grinding environment, you can make the right decision and optimize both cost and efficiency.