Steel Ball / Casting Balls

Category Steel Ball

-

(1) Chromium alloy casting balls are used in mine,thermal power, construction and chemical industry widely.

(2) Our company's cast steel balls and steel forgings are produced by a fully automated production line, and the quenching and tempering is completed by a fully automatic quenching and tempering integrated production line, with the industry's high level of smelting, heat treatment and other comprehensive casting capabilities.

(3)High hardness, low wear rate, smooth appearance, no porosity and save energy conservation and protect enviroment are the characteristics of our company's products, and the products are completely suitable for highly corrosive materials or environments.

(4)Our company will adjust the chemical composition of molten iron (especially the chromium content) according to the needs of customers, and adjust the manufacturing process to meet customer needs.

Product Description

-

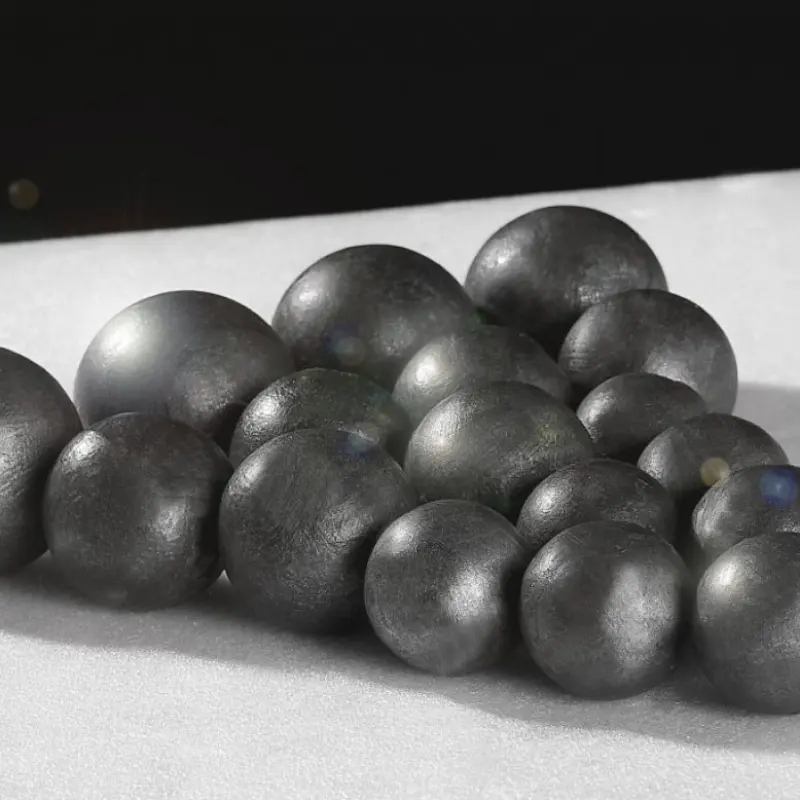

Outlet high quality casting balls, high hardness, low wear rate, are used in mine, thremal power, construction and chemical industry widely

Product Picture

Products Parameters

1.Low and medium chromium alloy casting ball

1)Chemical

| ITEM | Chemical Composition(%) | ||||||

| C | Si | Mn | Cr | Mo | P | S | |

| ZQCr 2 | 2.0-3.3 | ≤1.2 | 0.3-1.0 | 1.0-3.0 | 0-1.0 | ≤0.10 | ≤0.10 |

| ZQCr 5 | 2.0-3.3 | ≤1.2 | 0.3-1.0 | 4.0-6.0 | 0-1.0 | ≤0.10 | ≤0.10 |

| ZQcr 8 | 2.1-3.3 | ≤2.2 | 0.3-1.0 | 7.0-10.0 | 0-1.0 | ≤0.10 | ≤0.06 |

2)Properties and Microstructure

| ITEM | HRC | ak(j/cm²) | Microstructure | Time Falling of Balls |

| after tempering | ||||

| ZQCr 2 | ≥45 | ≥1.6 | P+C | ≥8000 |

| ZQCr 5 | ≥47 | ≥2.0 | P+C | ≥8000 |

| ZQcr 8 | ≥50 | ≥2.0 | M+P+C | ≥8000 |

C-Carbide P-Pearlite M-Martensite

2.High and super high chromium alloy casting ball

1) Chemical Composition(%)

| ITEM | Designation | Chemical Composition(%) | ||||||

| C | Si | Mn | Cr | Mo | P | S | ||

| High and super chromium alloy casting balls | ZQCr 26 | 2.0-3.3 | ≤1.2 | 0.3-1.5 | 23.0-30.0 | 0-3.0 | ≤0.10 | ≤0.06 |

| ZQCr 20 | 2.0-3.3 | ≤1.2 | 0.3-1.5 | 18.0-23.0 | 0-3.0 | ≤0.10 | ≤0.06 | |

| ZQCr 15 | 2.0-3.3 | ≤1.2 | 0.3-1.5 | 14.0-18.0 | 0-3.0 | ≤0.10 | ≤0.06 | |

| ZQCr 12 | 2.0-3.3 | ≤1.2 | 0.3-1.5 | 10.0-14.0 | 0-3.0 | ≤0.10 | ≤0.06 | |

2)Properties and Microstructure

| ITEM | Designation | HRC | ak(j/cm²) | Microstructure | Time of Falling Balls | |||

| after quenching | before quenching | |||||||

| High and super chromium alloy casting ball | ZQCr 26 | ≥58 | ≥45 | ≥4.0 | M+C | ≥10000 | ||

| ZQCr 20 | ≥58 | ≥45 | ≥3.5 | ≥10000 | ||||

| ZQCr 15 | ≥58 | ≥49 | ≥3.0 | ≥10000 | ||||

| ZQCr 12 | ≥58 | ≥49 | ≥3.0 | ≥10000 | ||||

M-Martensite C-Carbide

3)Product Specification and Weight

| Ball Diameter(mm) | Weight of per ball (kg) | Pcs/ton |

| Φ20 | 0.034 | 31058 |

| Φ25 | 0.063 | 15873 |

| Φ30 | 0.11 | 9091 |

| Φ40 | 0.26 | 3891 |

| Φ50 | 0.51 | 2000 |

| Φ60 | 0.86 | 1153 |

| Φ70 | 1.37 | 729 |

| Φ80 | 2.05 | 487 |

| Φ90 | 2.90 | 345 |

| Φ100 | 4.00 | 250 |

| Φ110 | 5.30 | 188 |

| Φ120 | 6.80 | 147 |

| Φ125 | 7.75 | 129 |

| Φ130 | 8.74 | 114 |

| Φ150 | 13.5 | 74 |