Table of Contents

The grinding ball is a key element in the milling process, where it plays an important role in reducing the size of materials through collision and grinding. The effectiveness of the grinding process largely depends on the characteristics of the grinding balls. Below are the main ways grinding balls affect the grinding process:

1. Grinding Ball Size

Impact on Efficiency: The size of the grinding ball significantly affects the grinding process. Larger balls are suitable for coarse grinding, as they provide more force to break down larger particles. Smaller balls are ideal for fine grinding, as they create a higher number of impacts per unit of time, improving particle size reduction.

Ball Size Distribution: Using a variety of ball sizes helps to optimize the grinding process by providing a more consistent breakdown of materials.

2. Ball Hardness

Wear Resistance: Harder balls tend to last longer as they resist wear more effectively, especially when grinding tougher materials. For example, in mining or cement industries, hard balls such as chrome steel are typically used for their durability.

Material Breakdown: If the ball is too soft, it may not break the material efficiently. On the other hand, excessively hard balls can wear down the mill itself and generate excess heat.

3. Ball Material

Steel Balls: Steel balls are commonly used in many industries due to their high hardness and wear resistance. They are well-suited for heavy-duty grinding applications.

Cast Iron Balls: Cost-effective but prone to faster wear, these balls are often used in mining and cement industries, where high-impact grinding is common.

4. Ball Quantity and Efficiency

Ball Load: The quantity of balls in the mill affects grinding efficiency. Too few balls can lead to ineffective grinding, while too many can create overcrowding, wasting energy.

Ball-to-Material Ratio: The optimal ratio of balls to material is essential for efficient grinding. Too many balls may result in inefficient energy use, while too few balls can hinder the grinding process.

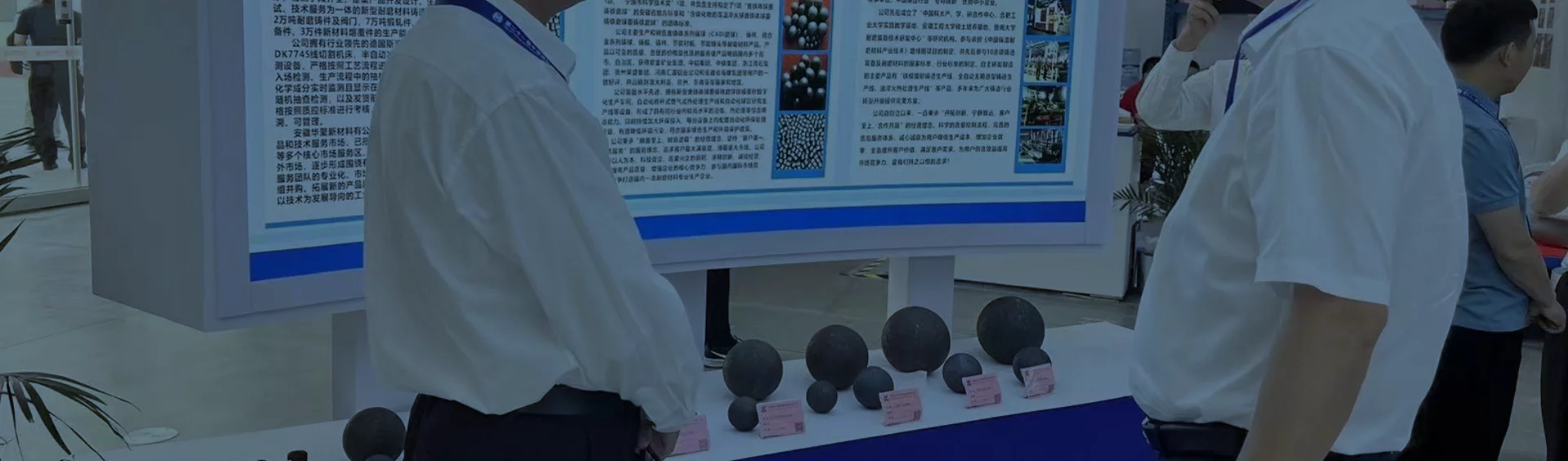

5. Grinding Ball Shape

Spherical Balls: The most common type of ball, spherical balls provide uniform grinding. They help maintain consistency in particle size reduction.

Irregular-Shaped Balls: These may provide more aggressive grinding due to their uneven surfaces, leading to higher friction but possibly causing inconsistent grinding.

6. Ball Wear and Its Impact

Effect on Product Quality: Over time, grinding balls wear out, and this can result in the production of smaller particles or contamination of the product. Worn balls can also lead to more frequent maintenance and higher operational costs.

Maintenance Needs: Regular replacement of worn balls is essential to maintaining consistent product quality and ensuring the smooth operation of the mill.

7. Conclusion

The grinding ball plays a crucial role in the efficiency and effectiveness of the grinding process. Factors such as size, hardness, material, quantity, and wear all influence how well the grinding mill performs. By selecting the right steel grinding balls for specific needs, industries can optimize their grinding processes, improve efficiency, and reduce costs.