Table of Contents

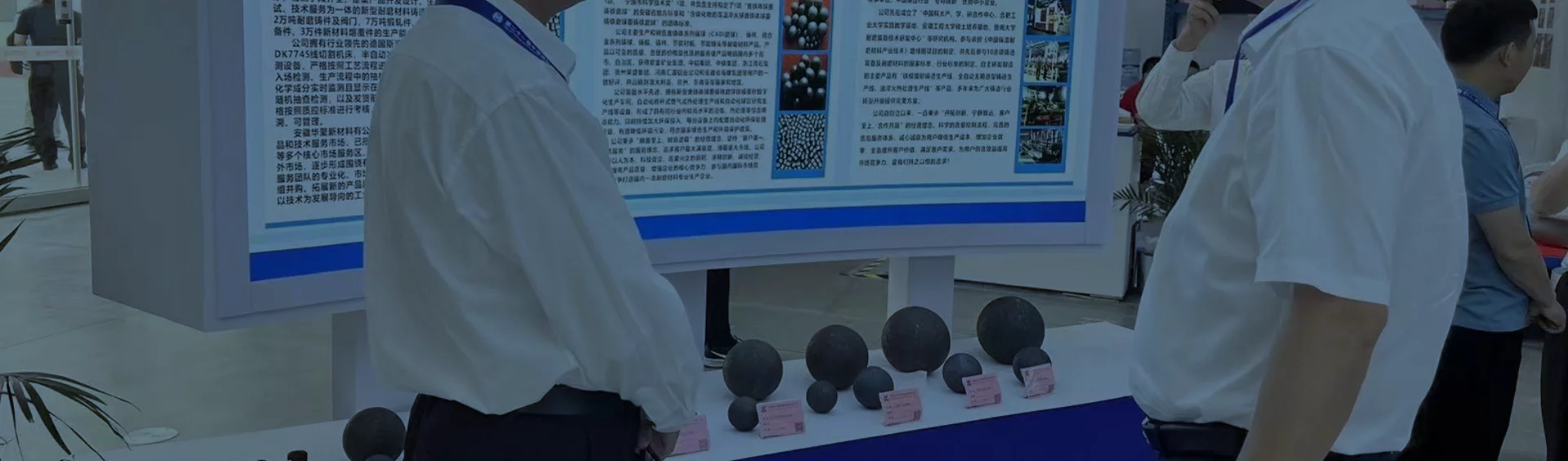

In the mining industry, extracting ore is just the first step. The real challenge lies in effectively crushing and grinding the mined ore, as this directly affects downstream beneficiation efficiency and metal recovery rates. The ball mill is the most common ore grinding equipment, and its core consumables are grinding balls. Though small in size, grinding balls play a crucial role in improving production efficiency and controlling costs for mining companies.

1. Improving Grinding Efficiency

Once ore enters the ball mill, it needs to be crushed through the impact and friction of grinding balls. If the material, hardness, and diameter of the grinding balls are well matched, the ore can be ground to the required particle size more quickly, thereby improving efficiency.

Proper diameter distribution: Larger balls are used for breaking coarse particles, while smaller balls are used for fine grinding. A balanced mix ensures optimal energy utilization.

High hardness material: Harder balls have better wear resistance, ensuring stable grinding performance and reducing wear.

Efficient grinding means shorter processing times and lower electricity consumption. For large-scale mining operations, this translates into significant cost savings.

2. Reducing Production Costs

Grinding balls are consumables, and their wear rate directly affects procurement and replacement costs. Low-quality grinding balls wear out quickly, requiring frequent replacement and causing downtime that reduces output. In contrast, high-quality grinding balls last longer, maintain consistent performance over extended periods, and reduce maintenance and labor costs.

Moreover, higher grinding efficiency reduces energy consumption. Since high-performance ball mills are energy-intensive, improved efficiency lowers the energy required per ton of ore processed, further reducing costs.

3. Enhancing Recovery Rates

Grinding quality directly impacts how well valuable metals are released from the ore. If grinding is too coarse, metals cannot be fully separated; if it is too fine, energy consumption increases and beneficiation becomes more difficult. The right grinding balls ensure that the ore reaches an optimal particle size, improving recovery rates and maximizing profitability.

4. Market Trends and Applications

In mining regions such as Africa and South America, high-chrome alloy and forged grinding balls are increasingly replacing traditional low-chrome cast balls. These advanced balls offer superior wear resistance and impact toughness, making them suitable for long-term, continuous operation in large mines. With growing emphasis on energy efficiency and sustainable practices, high-performance grinding balls are becoming the market standard.

Conclusion

Grinding mill balls may be small, but they are indispensable in ore grinding processes. By selecting high-quality balls with the right specifications, mining companies can significantly improve grinding efficiency while reducing energy use, maintenance, and operating costs. For companies aiming for long-term competitiveness, investing in high-performance grinding balls is a smart and strategic decision.