Table of Contents

In the mining and mineral processing industry, grinding is one of the most critical and energy-intensive stages of production. To achieve effective size reduction of ores and minerals, grinding media play a decisive role. Among various grinding media options, casting balls have become one of the most widely used solutions in mining and mineral processing plants worldwide. Their popularity is driven by a combination of performance, cost efficiency, and adaptability to demanding operating conditions.

Excellent Wear Resistance for Harsh Mining Environments

Mining operations often involve hard, abrasive ores such as iron ore, copper ore, gold ore, and various non-ferrous minerals. Casting balls, especially high chrome casting balls, are designed to withstand continuous impact and abrasion inside ball mills. Their metallurgical structure, enhanced through controlled alloy composition and heat treatment, provides high hardness and superior wear resistance.

As a result, casting balls maintain their shape and grinding efficiency over long operating cycles, reducing excessive wear and minimizing the frequency of media replacement. This durability is a key reason why mining companies rely on casting balls for large-scale mineral processing.

Consistent Grinding Performance and Stable Quality

Compared with some alternative grinding media, casting balls offer more consistent hardness distribution and dimensional accuracy when produced under strict quality control. Uniform ball size and hardness help ensure stable grinding behavior inside the mill, which directly affects particle size distribution and downstream processing efficiency.

Stable performance is especially important in mineral processing, where fluctuations in grinding efficiency can impact flotation, leaching, and separation processes. By using high-quality casting balls, operators can achieve more predictable milling results and better overall process control.

Cost-Effective Solution for Large-Scale Operations

Mining and mineral processing plants consume massive quantities of grinding media every year. Casting balls are generally more cost-effective than forged balls for many applications, particularly when considering long-term consumption rates and replacement cycles.

Their longer service life and lower wear rate translate into reduced operating costs, including lower media consumption, less downtime for mill maintenance, and decreased labor costs. For high-throughput mining operations, these savings can be substantial over time.

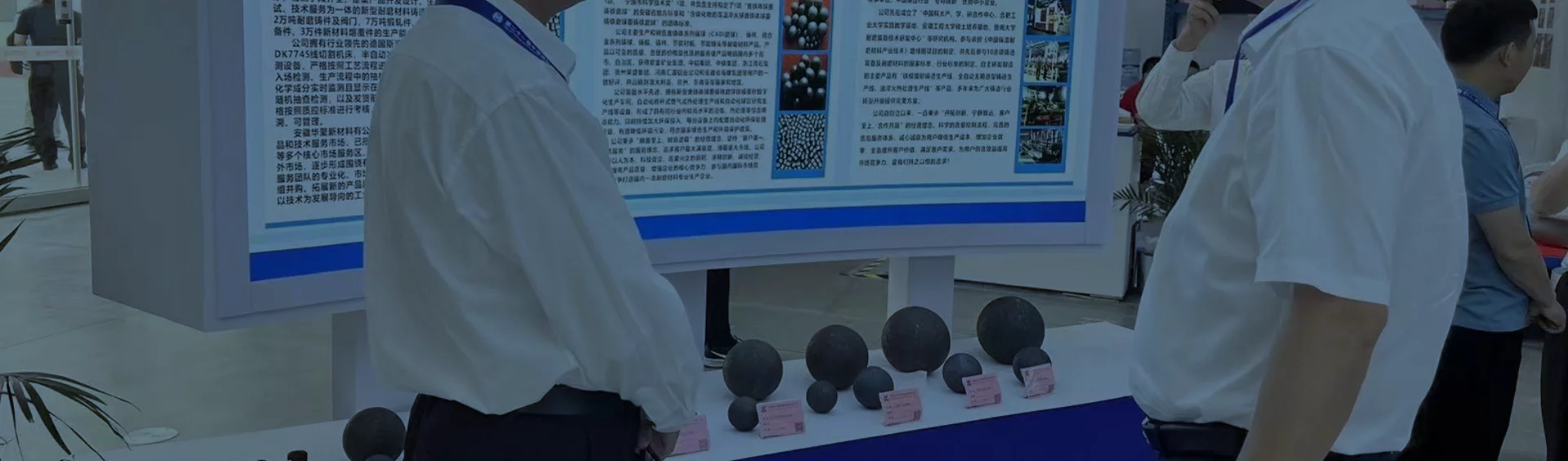

Wide Range of Sizes and Material Options

Wear-resistant Casting balls are available in a broad range of diameters, allowing them to be tailored to different mill sizes and grinding stages, from coarse grinding to fine milling. Additionally, manufacturers can adjust chemical compositions—such as chromium content—to meet specific ore characteristics and operating conditions.

This flexibility makes casting balls suitable for various mineral processing applications, including:

- Gold and silver ore grinding

- Copper and zinc beneficiation

- Iron ore and pelletizing processes

- Cement raw material and clinker grinding

Their adaptability is a major factor behind their widespread adoption across the mining sector.

Improved Energy Efficiency in Grinding Systems

Efficient grinding is not only about reducing particle size but also about minimizing energy consumption. Well-designed casting balls can improve impact efficiency and grinding kinetics inside the mill, leading to better energy utilization.

By maintaining optimal ball shape and surface condition during operation, casting balls help reduce unnecessary energy losses caused by excessive friction or irregular wear. This contributes to lower power consumption per ton of processed material, an increasingly important consideration as mining companies focus on energy optimization and sustainability.

Proven Reliability and Global Availability

Casting balls have been used in mining and mineral processing for decades, making them a well-proven and trusted grinding medium. Today, reliable manufacturers supply casting balls to mining operations around the world, ensuring stable availability, technical support, and consistent quality.

This global supply chain reliability further reinforces the position of casting balls as a preferred choice for mining companies seeking dependable, scalable grinding solutions.

Casting balls are widely used in mining and mineral processing because they offer an optimal balance of wear resistance, cost efficiency, performance stability, and application flexibility. Their ability to withstand harsh operating conditions while delivering consistent grinding results makes them an essential component of modern mineral processing systems. As mining operations continue to expand and optimize efficiency, casting balls will remain a critical and reliable grinding media solution.